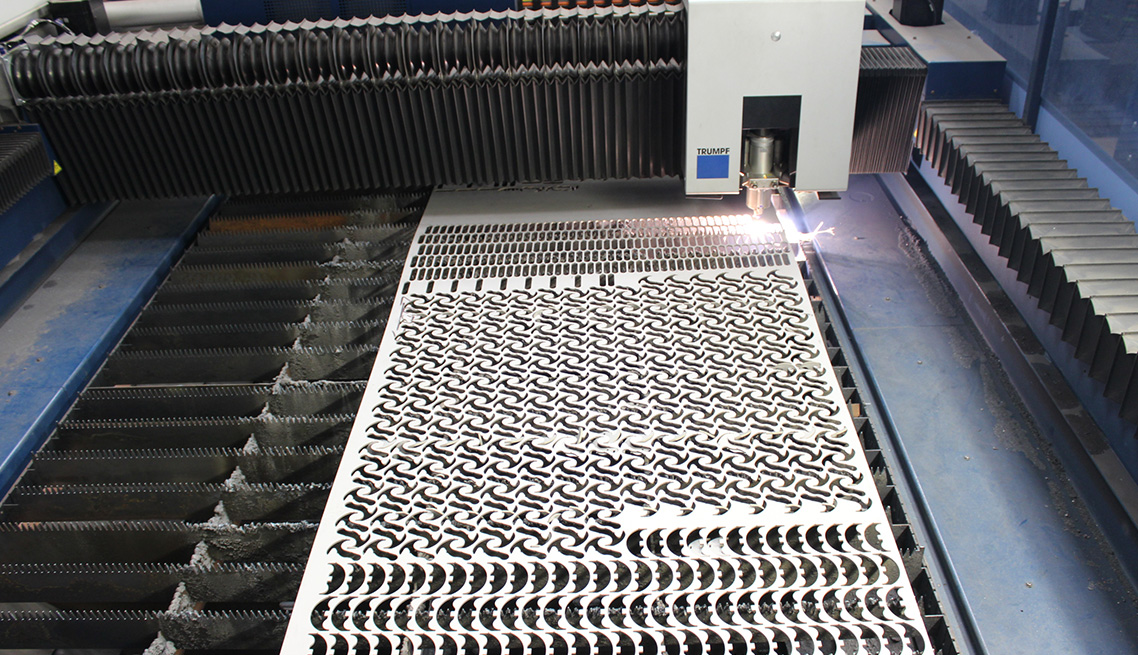

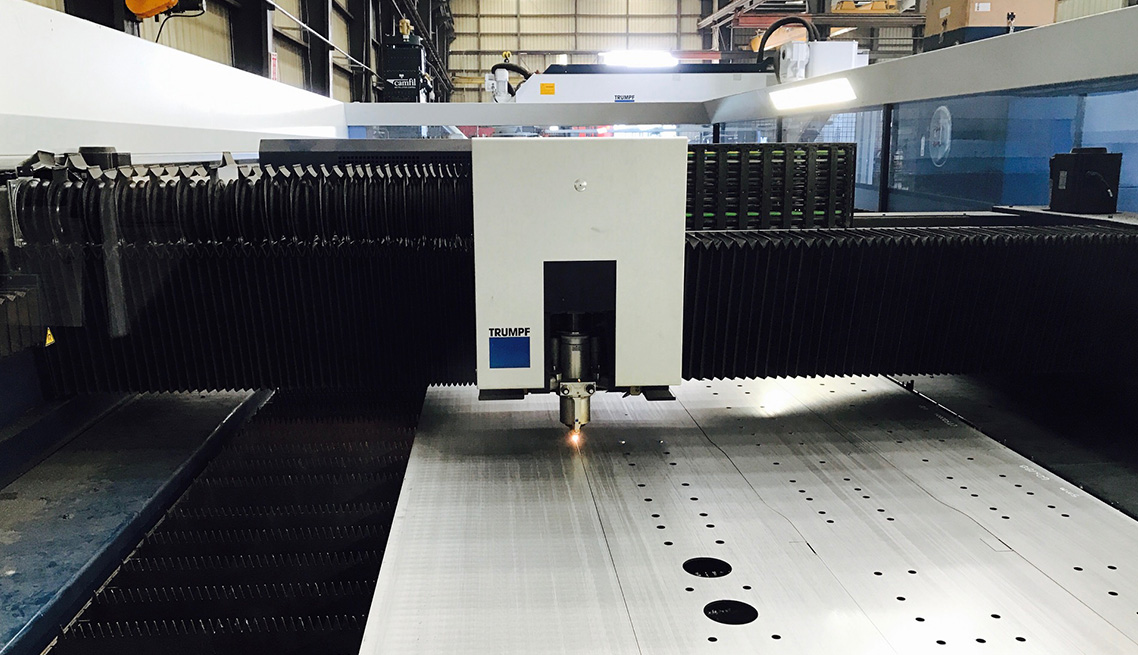

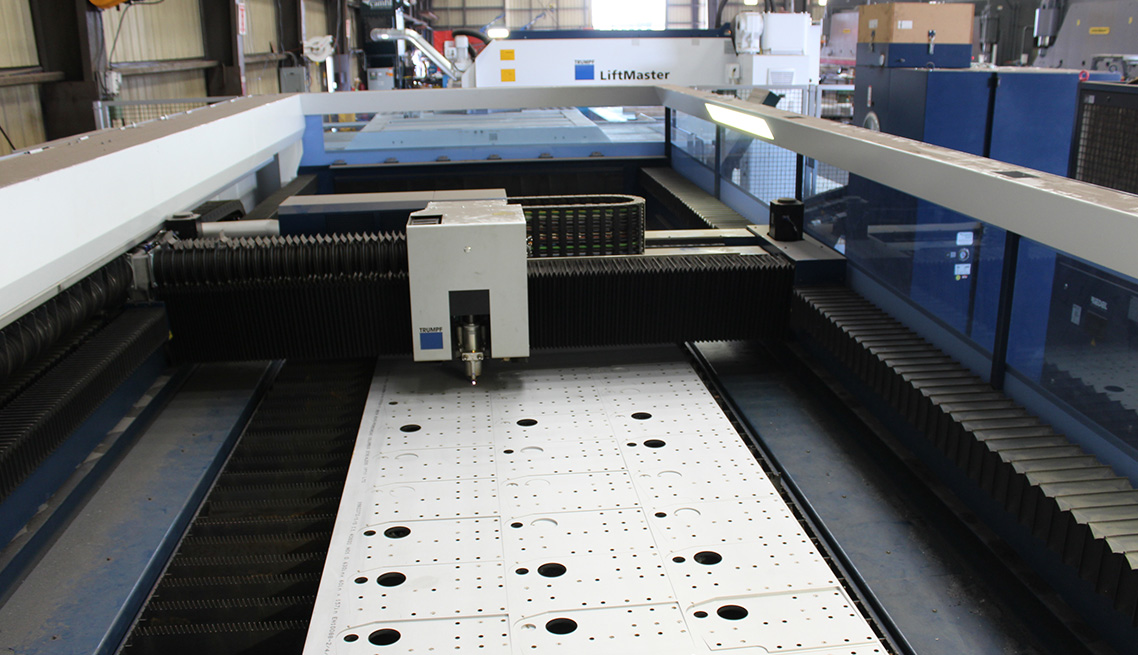

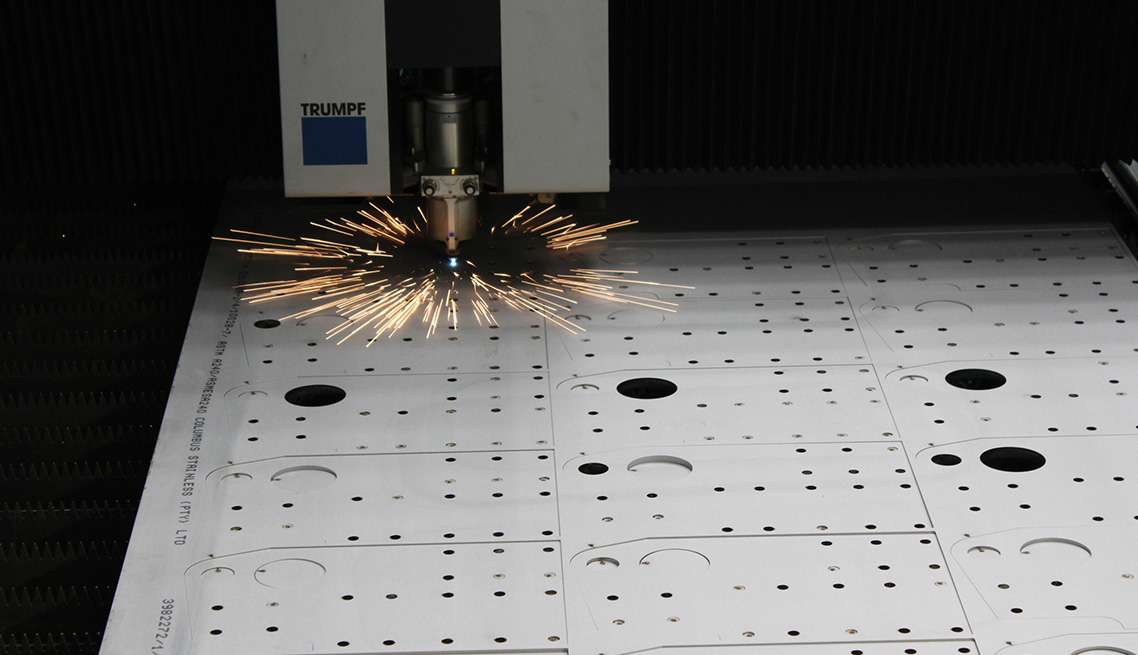

At Hogan Mfg., Inc. our metal manufacturing team use state-of-the-art sheet metal forming and cutting machinery to hold the tightest tolerances for your project.

Cutting & Forming

Cutting Centers

| Item | Qty | Description |

|---|---|---|

| CNC Lasers | 2 | Trumpf Trulaser 3030 4KW 5’ x10’ |

| 1 | Trumpf Trulaser 5060 6KW 6’ x 20’ | |

| 1 | Amada FOM2 4KW 5’ x 10’ | |

| 1 | Amada EMLK 3610 Punch/Laser combo 4KW/33Ton 5’ x 10’ | |

| CNC Plasma | 1 | AKS Cutting System – Cut up to 2″ thick plate, include beveling, 400 amps |

| CNC Tube Plasma | 1 | AKS cutting System – 2’ wide processing area |

| Up to 8″ x 8” rectangular and square tube | ||

| Up to 10” OD round pipe | ||

| Vertical Band Saws | 3 | 14″ High x 18″ Wide |

Forming Equipment

| Item | Qty | Description |

|---|---|---|

| Bending Robot | 1 | Trumpf Bend master 230 ton, 12’ bed, 250lb part cap |

| CNC Break | 8 | Trumpf Trubend 230 ton, 6 axis back gauge, 10’ bed |

| Trumpf Trubend 170 ton, 5 axis back gauge, 10’ bed | ||

| Trumpf V130 ton, 5 axis back gauge, 10’ bed | ||

| Cincinnati 750 Ton 24’ bed | ||

| Cincinnati 600 Ton 20’ bed | ||

| Cincinnati MF 175 ton, 5 axis back gauge, 8’ bed | ||

| Cincinnati MF 90 ton, 5 axis back gauge, 8’ bed | ||

| Cincinnati AF 350 ton, 5 axis back gauge, 18’bed |